Medical Devices

We drive advanced technology and innovation forward with our ceaseless R&D endeavors.

Technology

Overview

MOLECULAR DYNAMICS

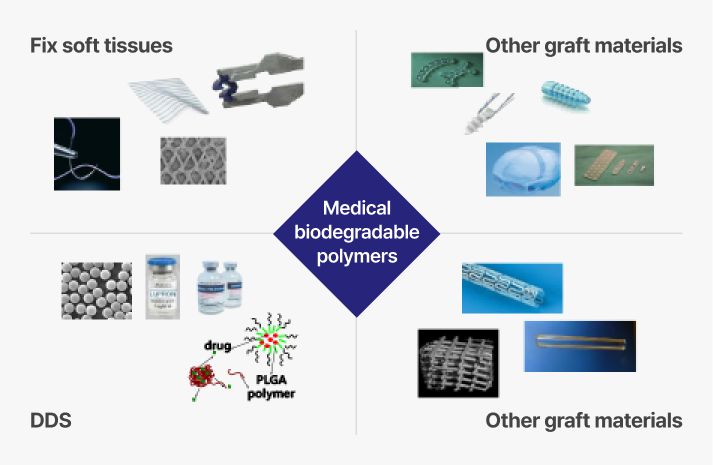

We use synthetic and natural absorbable polymer materials that have high biocompatibility to facilitate the recovery of wounds and also have the technology to design and develop safe low-toxic products that can be used to replace damaged physical areas.

Biodegradable

Polymer

We develop biodegradable polymers using medical aliphatic polyester that is decomposed and absorbed inside the body after the surgery after a certain amount of time and also develop devices for bioimplant using this biodegradable polymer.

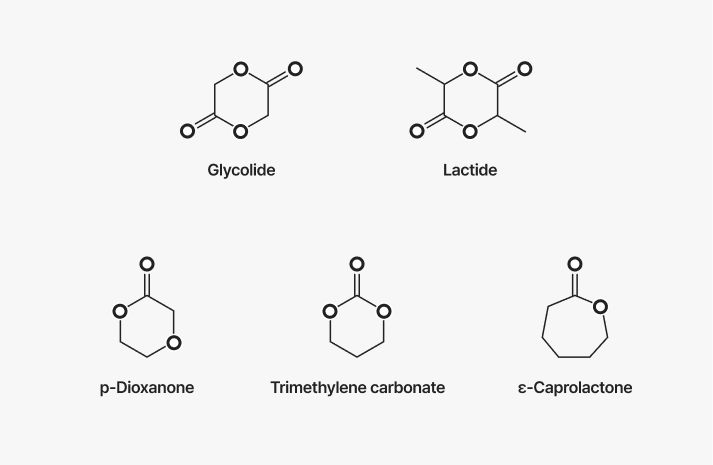

Samyang Biopharm’s main technology related to biodegradable polymer synthesizes lactone monomers (glycolide, lactide, p-dioxanone, etc.) into polymers with various compositions and equal amount of molecules according to strength and decomposition time. Through the fine processing of the synthesized polymer with this technology, we can produce absorbable surgical devices, such as high-strength Surgical Suture Material and surgical mesh, orthopedic implant and absorbable stents.

In addition, we can synthesize polymers with ultra-high molecular weight (UHMW), which are used for high-strength biodegradable surgical devices.

Oxidized

Regenerated

Cellulose

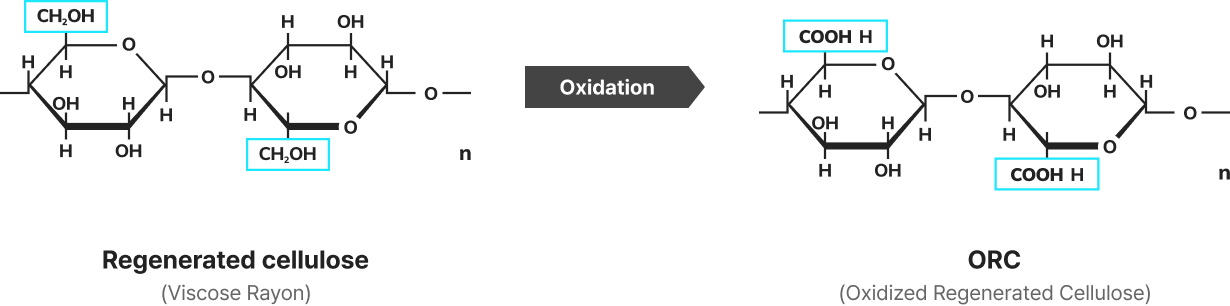

Technology for converting cellulose into oxidized regenerated cellulose (ORC), which is a biodegradable material that can be used in the human body, using various oxidization reactions

Using the technology of controlling the microstructure and oxidization level of the cellulose matrix, we can develop hemostatic agents with various hemostatic effects and anti-adhesion agents.

It is a technology that can control the hemostatic and anti-adhesion functions according to the level of carboxyl group (COOH) based on the oxidization conditions.

-

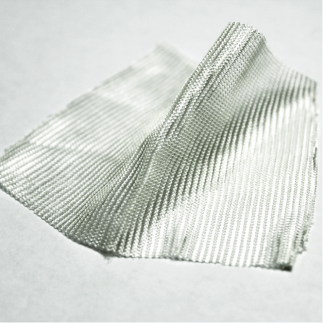

Knit

-

Fabric

-

Fibrillar

-

Non-Woven

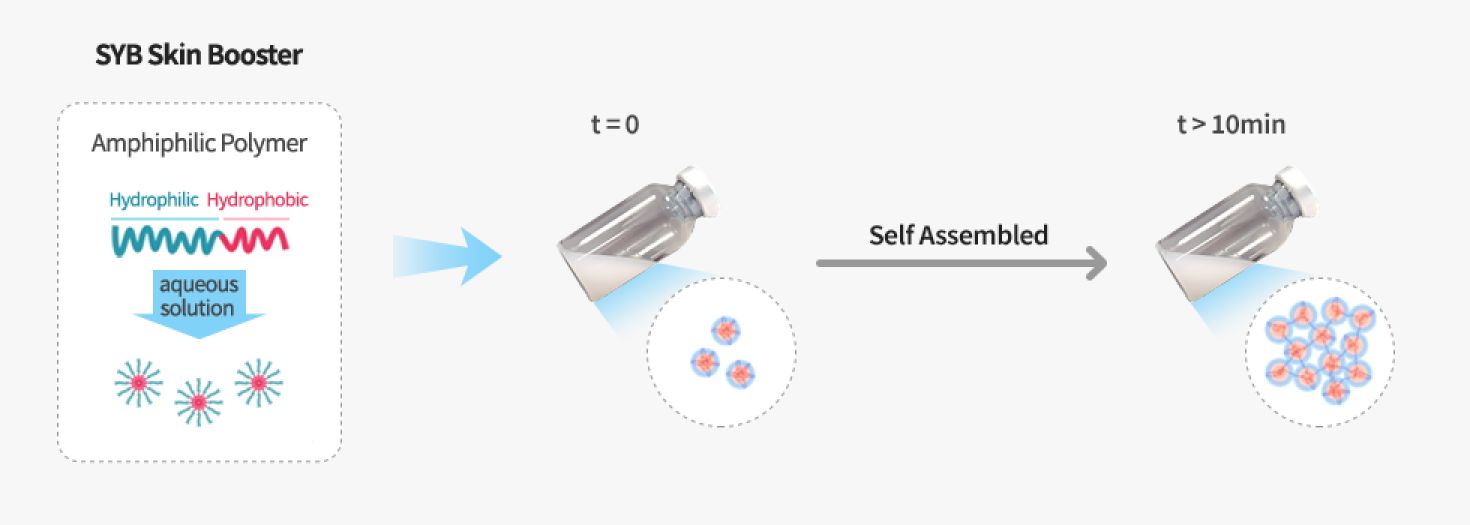

Self Assembled

Amphiphilic

Polymer

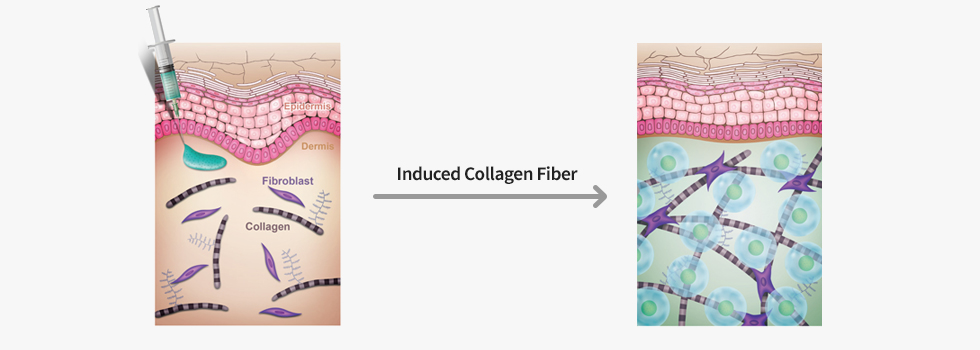

Technology that produces amphiphilic biodegradable polymer in nano-size particles to produce hydrogel real-time in the aqueous state using high surface energy

This technology enables the injection of nanoparticles inside the body in the aqueous state using the self-assembly technology, which is then gelated preventing the engulfing by macrophages and induces the generation of collagen. It can be used for fillers or skin boosters in medical aesthetics.

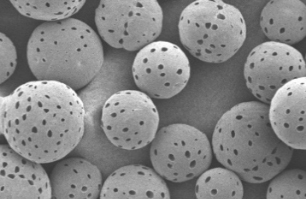

Porous

Polymeric

Microsphere

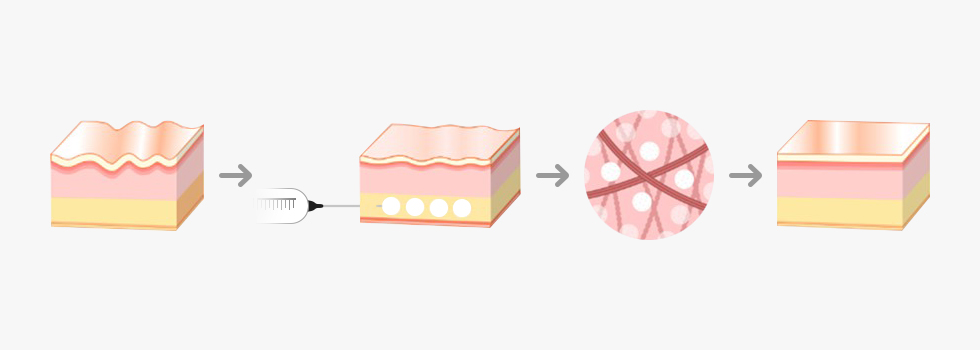

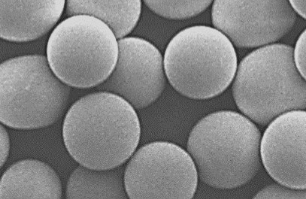

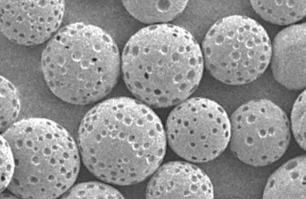

Technology that produces biodegradable polymers (PCL, PLA, PLGA, etc.) in even-sized microspheres

The even-sized porous microspheres produced with the SEP (Samyang Biopharm's evenly-distributed porous particle) Technology can be used to improve facial wrinkles by injecting them into the body.

They can also be produced in the desired form (non-porous microsphere, dimpled-surface microsphere, etc.) and size, making it applicable in various medical device areas.

-

Porous Type

-

Non-Porous Type

-

Dimple Type